- Home

- Products

- Submersible Pumps

- Xylem

- Sekamatik

- Lowara Sekamatik 400/800

Lowara Sekamatik 400/800 are High volume compact wastewater lifting stations

| Specifications |

| Flow: | up to 200 m3/h |

| Head: | up to 37 m |

| Volume (total): | up to 800 l |

| Power supply: | Single and three phase 50 Hz |

| Power: | from 0,9 kW up to 11,5 kW |

| Number of pumps: | 1 or 2 |

Sekamatik 400 and 800 lifting stations are fully automatic, compact, cost effective and odor free solution for handling wastewater in buildings.

It's the ideal solution whenever sanitary appliances are located at a lower level than the main gravity sewer system.

The Sekamatik 400 and 800 has one or two separately attached full size sewage pumps with channel or vortex hydraulics for problem free handling of wastewater. The size is suitable for large commercial and public buildings.

A tandem version of the Sekamatik 400 and 800 lifting stations with higher capacity is available.

Designed in accordance with EN 12050.

Lowara Sekamatik Wastewater Lifting Stations

Sekamatik series is a range of grey / rain water or sewage lifting stations ideal for larger private or public buildings. Motor power up to 11.5 kW with capacities up to 200 m3/h and storage tanks are available in plastic with volumes from 180 up to 800 liters.

The compact design allows an installation with minimum space requirement. Sekamatik 10 E 7M is a compact behind the toilet pumping station with cutter pump. Install a toilet anywhere, typically without any major construction.

COMPACT SEWAGE DISPOSAL UNIT WITH PLASTIC TANK.

The Sekamatik 400/800 range of compact sewage disposal units is suitable for pumping sewage and wastewater

from areas below the sewer level (see DIN EN 12056). With their large tank volumes and high performance

submersible wastewater pumps they are perfect for large private, commercial or public buildings, hospitals, schools etc.

The compact design allows installation with minimum space available.

The horizontal pump position with the straight-thru tank-pump discharge connection eliminates elbows.

The tanks are available with 400 and 800 liters volume.

DIN EN 12050-1: Conformity and design approved and controlled by LGA.

Pumped liquid: Clear water or drainage water, wastewater or sewage containing soft solids.

Max. liquid temperature: 35°C, short term up to 60°C.

Operation: Intermittent.

Specifications

Flood protected single or twin pump lifting station consisting of:

Collecting tank: Odour and gas tight tank.

Plastic tank: Total volume 400 lt, tandem installation with two tanks 800 lt volume.

Inlets:

- Horizontal: DN 150 (3x).

- Vertical: DN 100.

Air vent DN 70. Connection for diaphragm pump DN 50. Cleaning cover with screw cap. Connections for pneumatic

level control and float switch.

Pumps: Single stage sewage pumps. Horizontal installation, discharge vertical.

Impellers: Enclosed single-vane impeller or vortex impeller.

Motors: Fully submersible, pressure tight electric motors 400-415 V / 3 Ph. Thermal sensors embedded in the

winding. Insulation class H. Degree of protection IP 68. Large diameter stainless steel rotor shaft, pre-lubricated

bearings.

Seals: Combination of two mechanical seals (silicon-carbide) in a separate oil chamber. Oil inspection from outside.

Materials

| Collecting tank |

Polyethylene |

| Motor housing, pump housing, impeller |

Cast iron |

| |

GG25/EN-GJL-250 |

| Rotor shaft, screws |

Stainless steel |

| Seal kit |

NBR |

Technical Data

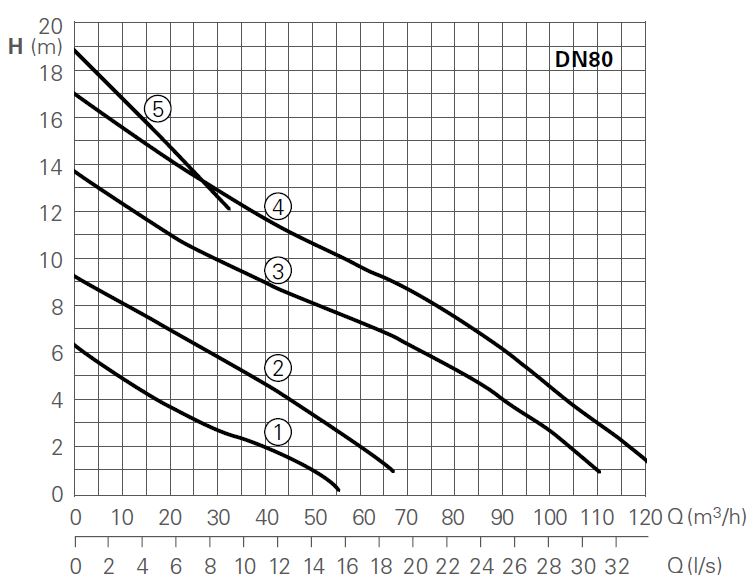

Curv

no. |

Pump

type |

Motor

output

P2 (kW) |

Speed

(rpm) |

Nominal

current

(A) |

Weight

(kg) |

| |

Discharge DN 80 |

|

|

|

|

| |

Spherical clearance 70 mm |

|

|

|

|

| 1 |

T4P0 87 0P EM . .1. 93T/4 D |

0,9 |

1450 |

2,6 |

40 |

| 2 |

T4P0 87 0P EM . .1. 163/T4 D |

1,3 |

1450 |

3,4 |

40 |

| 3 |

T4P0 87 0P EM . .2. 169/T4 D |

1,9 |

1450 |

5,5 |

66 |

| 4 |

T4P0 87 0P EM . .3. 214/T4 D |

2,4 |

1450 |

6,3 |

66 |

| 5 |

T4P0 87 0P EV . .3. 269/2T D |

2,9 |

2900 |

6,3 |

56 |

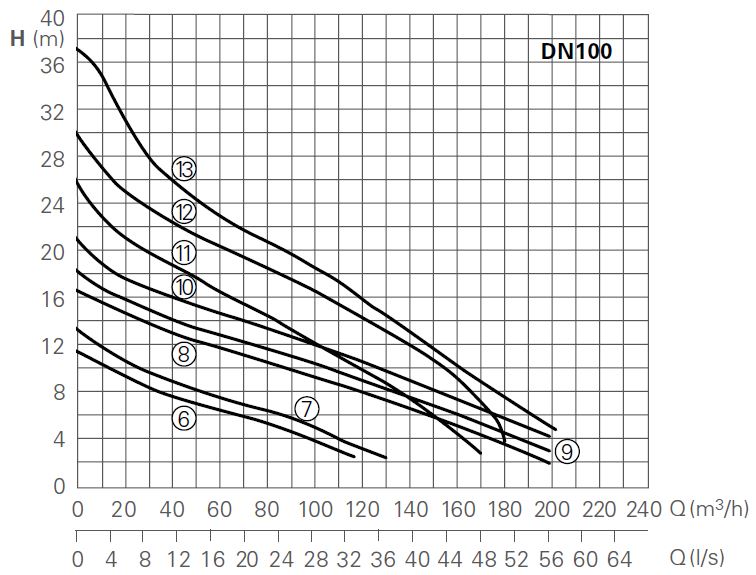

| |

Discharge DN 100 |

|

|

|

|

| |

Spherical clearance 80/100 mm |

|

|

|

|

| 6 |

M41X0 2 P3E3 .9..- D264T4A |

2,6 |

1450 |

6,2 |

71 |

| 7 |

M41X0 2 P3E4 .1..- D264T4 |

2,6 |

1450 |

6,2 |

71 |

| 8 |

M41X0 2 P4E4 .4..- T5504T |

5,0 |

1450 |

9,9 |

113 |

| 9 |

M41X0 2 P4E4 .6..- T6654T A |

6,5 |

1450 |

13,1 |

118 |

| 10 |

M41X0 2 P4E4 .8..- T6654T |

6,5 |

1450 |

13,1 |

118 |

| 11 |

M41X0 2 P3E3 .0..- T9752T |

9,5 |

2900 |

18,8 |

105 |

| 12 |

M41X0 2 P3E3 .1..- T18125 TA |

11,5 |

2900 |

22,2 |

110 |

| 13 |

M41X0 2 P3E3 .5..- T18125 T |

11,5 |

2900 |

22,2 |

110 |

Tank Types

| Type |

Material |

Total volume |

Operating volume |

| PE E/D |

Polyethylene |

400 l |

220 l |

| PE TD |

Polyethylene |

800 l |

440 l |

* 2 tanks in tandem installation

Combinations of tanks and pumps

| |

|

|

| Pump types |

available in combination with tank types: |

|

400 liters |

800 liters |

| 408 PE ... 9T |

E+D - |

- |

| 408 PE ... 13T |

E+D - |

- |

| 408 PE ... 19T |

E+D - |

- |

| 408 PE ... 24T |

E+D - |

- |

| 408 PE ... 29T |

E+D - |

- |

| 410 PE ... 26TA |

E+D |

TD |

| 410 PE ... 26T |

E+D |

TD |

| 410 PE ... 50T |

E+D |

TD |

| 410 PE ... 65TA |

E+D |

TD |

| 410 PE ... 65T |

E+D |

TD |

| 410 PE ... 95T |

E+D |

TD |

| 410 PE ... 115TA |

E+D |

TD |

| 410 PE ... 115T |

E+D |

TD |

Equipment supplied

Tank with 1 pump or 2 pumps. Elastic hose connections with bands for tank inlet, connection tank-pump, air vent and diaphragm pump. 1 Elastic union piece DN 100 per pump for discharge connection (with flange DN 80 or DN 100 depending on the pump type). Pneumatic level control. Electronic control panel.

Controls

Control panel Pneumatic level control with pressure operation. Available with float switch control on request. Electronic control box for control and monitoring of all main functions

Dimensions

| Station type |

Pump type |

Dimensions |

|

|

A A1 |

B |

C |

D |

E |

F |

G |

H |

K |

L |

M |

N |

| PE E ... / PE D ... |

9T - 13T |

1713 - |

- |

435 |

369 |

80 |

260 |

180 |

809 |

90 |

200 |

700 |

840 |

|

19T - 24 T |

1754 - |

- |

476 |

440 |

80 |

260 |

180 |

880 |

93 |

200 |

700 |

840 |

|

29T |

1750 - |

- |

472 |

369 |

80 |

260 |

180 |

809 |

90 |

200 |

700 |

840 |

|

26TA - 26T |

1769 - |

- |

491 |

400 |

100 |

300 |

190 |

890 |

93 |

200 |

700 |

840 |

|

50T - 65TA - 65T |

1946 - |

- |

668 |

480 |

100 |

300 |

190 |

970 |

130 |

200 |

700 |

840 |

|

95T - 115TA - 115T |

1896 - |

- |

618 |

400 |

100 |

300 |

190 |

890 |

93 |

200 |

700 |

840 |

| PE TD ... |

26TA - 26T |

1769 - |

- |

491 |

400 |

100 |

300 |

190 |

890 |

93 |

200 |

700 |

840 |

|

50T - 65TA - 65T |

1946 - |

- |

668 |

480 |

100 |

300 |

190 |

970 |

130 |

200 |

700 |

840 |

|

95T - 115TA - 115T |

1896 - |

- |

618 |

400 |

100 |

300 |

190 |

890 |

93 |

200 |

700 |

840 |

Performance

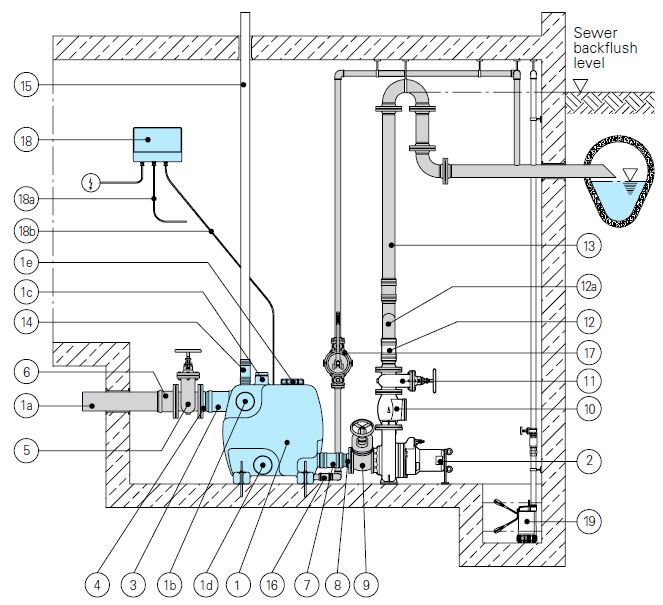

Installation

- 1. Collecting tank *

- 1a. Horizontal inlet

- 1b. Alternative horizontal inlet/upper tank

connection

- 1c. Vertical inlet

- 1d. Lower tank connection

- 1e. Cleaning cover

- 2. Sewage pump *

- 3. Elastic hose connector, inlet *

- 4. Flanged pipe socket

- 5. Flanged gate valve with gasket and

fixing bolts, tank inlet

- 6. Flanged socket with gasket an fixing

bolts

- 7. Elastic hose connector *

- 8. Flanged pipe socket *

- 9. Flanged gate valve with gasket and

fixing bolts, pump inlet

- 10. Flanged swing check valve with

gasket and screws, cleaning cover and

aeration fixture

- 11. Flanged gate valve with gasket and

fixing bolts, discharge pipe

- 12. Flanged elastic piece with gasket and

screws **

- 12a. Flanged union piece with gasket and

screws for twin pump station PE 40

ditto for twin pump station PE 80

- 13. Flanged discharge pipe consisting of:

- – Flanged FF-piece, gasket and screws

- – additional m

- – 90° flanged elbow with gasket and

screws

- – 180° flanged elbow with gasket and

screws

- 14. Elastic union piece for air vent pipe *

- 15. Air vent pipe

- 16. Elastic union piece for diaphragm pump *

- 17. Diaphragm pump

- 18. Control panel with pneumatic or float

switch level control*

- 18a. Power cable for pump motor

- 18b. Pneumatic pressure hose *

- 19. Submersible drainage pump

* equipment supplied

** equipment supplied depending

on pump discharge size