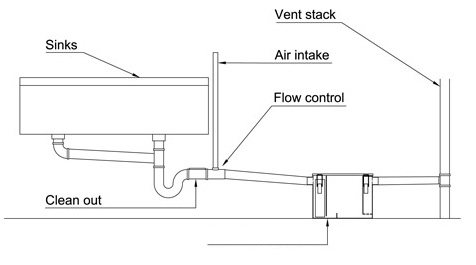

Our biological dosing fluid will keep your grease traps cleaner and keep your drains free of blockages caused by build ups of fat, oil and grease waste.

Full of fat-digesting, environmentally friendly bacteria, our fluid will help you maintain your grease traps. You will still need to empty and clean your grease traps, but the use of fluid will make it a much easier and quicker process.

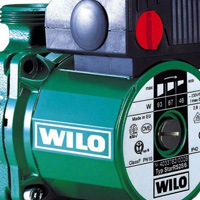

Our automatic dosing pump is designed to allow you to dispense our biological dosing fluid into your grease traps continuously over a 24/7 period. Each pump is easy to install and set up and comes with full instructions. We recommended each pump is set up to dispense 20litres of fluid into your grease trap over a 3 month period.