- Products

- Submersible Pumps

- WILO

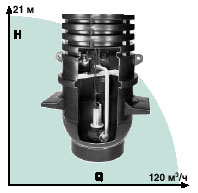

- Wilo Drainlift WS 1100 Sewage Lifting Plant

Pumping wastewater and sewage from building systems, rooms and from surfaces below the backflow level (EN 752/EN 12050).

| Type key Example: |

| WS |

Moulded PE sump pump station |

| 900 |

Sump diameter

900 = 900mm

1,100 = 1,100mm |

| E |

E = Single pump

D = Double pump |

| TP40s |

Selected pump type |

Wilo Fully self-contained wet sump pumping station with stainless steel pipework. Lightweight Polyethylene construction for easy installation. Two sump size for five types with anti-buoyancy provision as standard.

Applications

Collecting and displacing waste water and coarse sewage in conjunction with mechanical building services (single dwellings, residential buildings, underground car parks) originating from spaces amnd areas below backflow level (to DIN 1986/EN 12050). The outside of buildings without necessitating any concrete work. A time saving, easy installation and cost-friendly solution for any planner or proprietor. Variable installation depths are achieved by shortening the sump collar for lower depths or by adding a sump collar extension for greater depths.

suitable as a fully self-contained wet sump station in conjunction with pressurised displacement and as collecting pumping station in conjunction with non-pressurised drainage.

Applicable Product Types:

The Wilo-Drainlift WS is a complete packaged pumping station manufactured from synthetic materials utilising the very latest production technology.

Wilo-DrainLift WS900 Economy:

The Wilo-DrainLift WS900 Economy utilises integrated float switch control and thus eliminates the need for a separate control panel. Ideal for those applications where an economy price is required.

Wilo-DrainLift WS900:

The Wilo-DrainLift WS900 is a 900mm Dia.packaged lifting station complete with control panel and high level alarm.

Wilo-DrainLift WS1100:

The Wilo-DrainLift WS1100 is a 1100mm Dia. packaged lifting station complete with control panel and high level alarm.

Applicable Pump Types:

Wilo TP50:

For heavily contaminated fluids, 48mm free ball passage, detachable power cable.

Wilo TP65:

For heavily contaminated fluids, 48mm free ball passage, detachable power cable.

Wilo TP80:

For heavily contaminated fluids and faeces, 78mm free ball passage, Explosion protected as standard, detachable power cable. (single pump station only)

Wilo MTS 40s:

For heavily contaminated fluids and sewage. With patented macerator:

- Inside rotating blade

- Conically designed macerator

- Absolutely reliable operation

All ranges of above pumps available in

1phase (240v) or 3phase (415V) with explosion proof motors.

Please call for further information

Design and Equipment

- Maximum working load 5 kN/m2 (in accordance with DIN EN 124. Group 1)

- Maximum pressure in the pressure line 6 Bar

- Wet sump pumping station for recycling-capable PE

- Extreme safety from floating due to 2/4 side-fitted finms as standard (WS 900 = 2, WS1100 = 4) side fins fitted as standard (no concrete rings required)

- 2/4 inlets selectable optionally selectable on site

- Maximum strength due to the semi-circular construction of the sump bottommmmmm which gives high rigidity and optimum swirling action to prevent deposit formation

- Wilo above-water coupling arrangemment

- Two sockets DN100 for vet connection and and power cable

- Easy access to the rod suspended float controller

- Scouring connection as standard

Scope of delivery

The standard equipment for dual pump station double the quantited of above the water couplings and fittings

- Stainless steel discharge pipe from pump discharge port to approx. 10cm outside the shaft

- Above water coupling system including sealing gaskets

- Non-return valve, isolating valve completely installed

- 11/2" scouring connection

- Stainless steel chain including fixing hook

- Holding pipe for level monitoring (level sensor Type N Float switch)

- Installation and operating manual

Mechanical Accessories for DrainLift WS900/1100 sump pump station and WS Economy

Wilo DrainLift - High level alarm battery operated high level alarmm and float switch for WILO-DrainLift WS900 Economy.

Wilo DrainLift - Sump shaft extensions made of PE (dia. 730mm x 800mm), incl. installation accessories, seal and holding rod extension for level sensor (custom lengths available upon request). Extensions may not be connected to each other, A maximum of 1 extension is possible per shaft.

Wilo DrainLift - Sump cover standard made of PE "Standard" (dia. 830mm), incl. non-slip profile on the top side and two locks on the inside. Class A for pedestrian traffic.

Wilo DrainLift - Sump cover flood proof made of PE "Submersible" (dia 830mm x 100mm), incl. non-slip profile on top and six stainless steel locks for locking to the outside. Class A for pedestrian traffic.

Clamping connector made of PE for out discharge pipe connection outside of the sump

- 11/2" (Rp(JG)) with 50mm outer dia.

- 11/2" (Rp(JG)) with 65mm outer dia.

- 2" (Rp(JG)) with 63mm outer dia.

Product Advantages Wilo-Drainlift WS

- Sediment-free collection chamber

- Maximum stability due to hemispherical bottom

- 2/4 inlets selectable on-site