- Home

- Products

- Booster Sets

Southern Pumps Services are professionals in pump technology across all building services.

Lowara is a leading supplier of pump technology to the building services industry. Thousands of commercial and residential applications rely on Lowara pumps, day in day out for their booster pump applications.

Cold Water Booster Sets

The GEN booster sets are built in conformity with EN12845 for automatic sprinkler systems and with UNI10779 for hydrant systems.

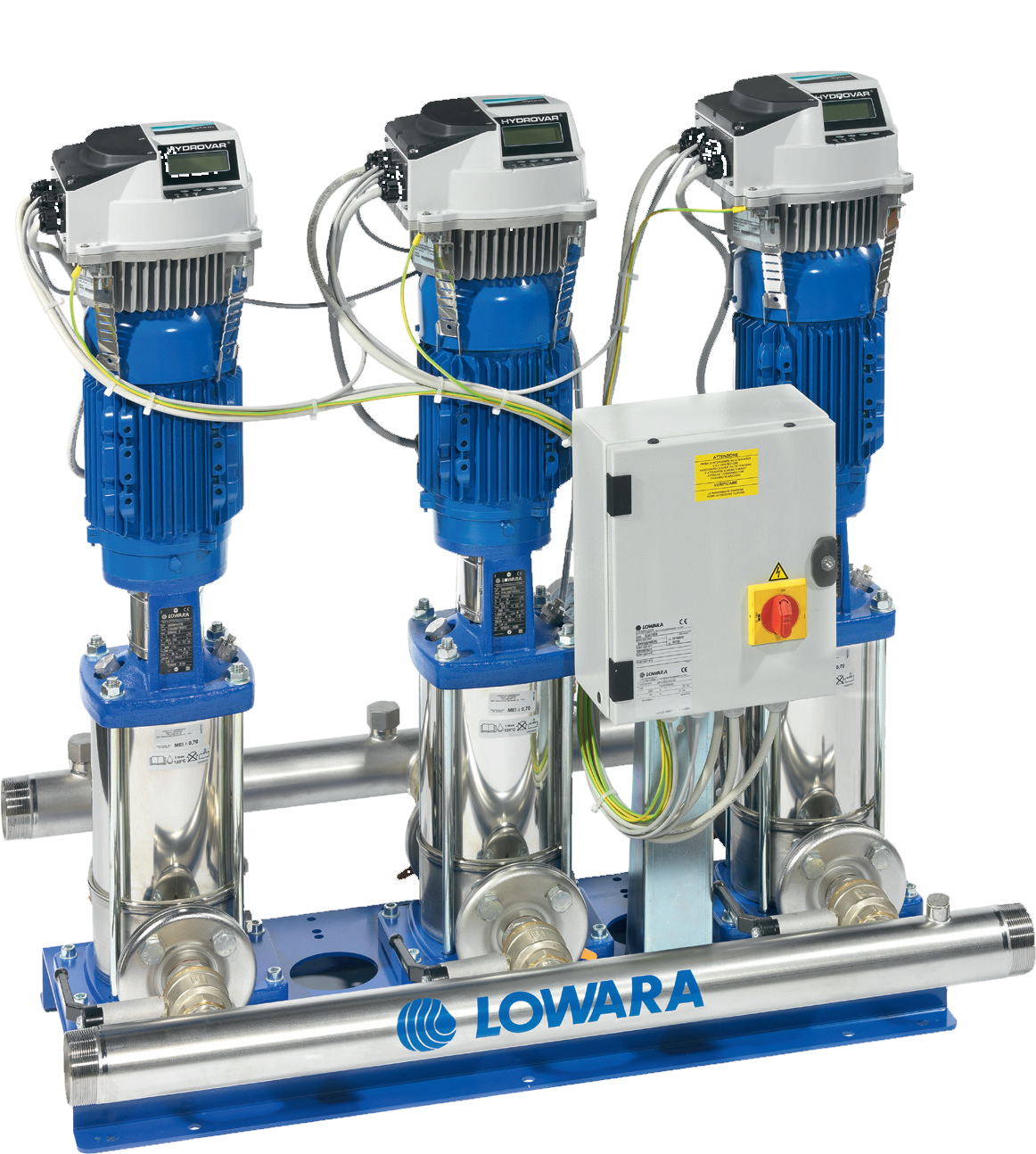

The Lowara GHV series booster sets are fully automatic booster sets for water supply. They are equipped with 2-4 variable speed pumps with a Hydrovar pump controller, pressure transmitters and control panel, all mounted on a frame for easy installation.

The Lowara GS series booster sets are fully automatic booster sets for water supply. They are equipped with 2-3 fixed speed pumps (where one can be a jockey pump), control panel, SM30 controller and pressure transmitters, all mounted on a frame for easy installation.

The Lowara GVF series booster sets are fully automatic booster sets for water supply. They are equipped with 2-6 pumps (where one can be a jockey pump), pressure transmitters and control panel with a SD60 controller and a variable frequency drive, all mounted on a frame for easy installation.

Extensive range of 2 pump sets controlled by pressure switches or pressure transmitters, with constant or variable speed operation. The range has been designed to supply water to domestic users on an intermittent and variable basis, using electric motors controlled from an electric panel.

Lowara’s Hydroquench packaged fire system is setting the standard in fire prevention and fighting in residential developments across the UK. The automatic sprinkler sets provide a pressurised system in and residential installations, using the latest technologies to ensure the highest degree of reliability.

Lowara Booster sets complete with break tank – suitable for boosting cold water via type A/B air gap on domestic, commercial, industrial and building applications, energy saving variable speed models available fitted with the Teknospeed.

Presfix pressurisation units are designed to replace water that has been lost through system leakage and to maintain the system design fill pressure in sealed heating and chilled water systems in accordance with BS7074 parts 1,2 & 3.

Resvari (Variable Speed) and Resfix (Fixed Speed) booster sets for domestic dwellings with integral water storage with type AB Air Gap. Single phase 230v. Ideal for increasing water pressure around the home.

The Lowara/Xylem Servitec Servitec 30 Vacuum Spray De-Aeration System automatically eliminates air from heating and chilled water systems in a quick and efficient manner

These units consist of a single-phase automatic one pump pressure set. It’s available in the electromechanical version, Sphere Units, Block (diaphragm tank, pressure switch, pressure gauge and various connectors) and in the electronic one (pump plus Genyo).

Lowara cat-5 packaged break tank booster sets designed to be both compact and cost effective.

The ResiBoost is a series of constant pressure systems for energy efficient residential water supply. It's a complete packaged solution including Lowara stainless steel pumps, a variable speed drive and all other necessary components in one package.

Q-Smart single-phase electronic control panel for 1 or 2 fixed speed pumps. Over 50 different combinations available within this one product that can be used for controlling pressure boosting or sewage applications.

Booster sets for electric submersible pumps made of stainless steel or galvanized steel for horizontal or vertical installations, well suited not only to new systems but also to existing pipelines.

The GHV booster set combines the highly reliable multistage e-SV pump with the new 5th generation Hydrovar® and is now available from stock or manufactured in 5 days plus delivery. Delivery times to be agreed with our sales office when you place your order.

Variable Speed Booster Sets

Wide range of 1, 2, 3 and 4 pump variable speed booster sets with individual transducers for each pump giving a very robust operating system.

Applications

Water supply to domestic dwelling and office buildings, hotels, shopping centers, factories, and greenhouses.

Water supply for agricultural use (irrigation systems).

Water supply to systems requiring constant pressure.

Introduction

Lowara booster sets have been designed to be both compact and cost effective. Both the TKS and Hydrovar range are built to exacting standards and as such are suitable for the harshest environments. Packaged sets are suitable to cover all building service applications from small domestic premises to large building complexes as well as Irrigation.

Reliable Controls

The control system in any booster set must be robust. The environment in which they operate can often be subject to power fl uctuations, induced spikes, RFI and EMI. Both the TKS and Hydrovar uses proven electronics to reduce exposure from all conditions normally encountered in theiroperating environment and will also ensure long periods of operation with minimal down time.This product has been fully tested and complies with the latest EC directives for EMC emissions and immunity, and the low voltage and machinery directives.

Pump Configuration

Southern Pumps Services Ltd can supply Lowara Hydrovar sets in many configurations:

- Single pump, full duty operation.

- Two pumps arranged as duty assist or duty standby.

- Three pumps arranged as duty-assist-assist or standby.

- Four pumps arranged as duty-assist-assist-assist or standby.

- TKS sets can be supplied as single or twin pump sets arranged for duty only, duty/assist or duty standby.

- GHV Series 'R' Version

- Ideal for limited space plant rooms with small footprint and compact design.

Installation and Service

Each set comes fully packaged complete with isolating valves, non return valves (Anti-vibration feet), and pressures sensors.

Small sets are provided with screwed manifolds whilst all other sets are provided with fl anged manifolds.

Pressure vessels are normally supplied separate from the base to keep the pump set size to a minimum for ease of shipping and manoeuvrability, however vessels can be integrated into the pump set when required. All pumps can easily be removed for servicing.

Lowara Pumps

Lowara have been manufacturing a large range of high quality end suction and vertical multistage pumps for many years. Booster set manufacturers have been quick to see the benefits of this range and many have incorporated them into there own booster set designs.

The Lowara range of booster sets have been designed and built to the same exacting standards as the pump range, this combination of building both pump and set results in an extremely reliable and cost effective solution to cold water boosting.

Booster Set Selection

In the majority of applications the booster set must be capable of providing the maximum probable simultaneous demand. As this demand is not normally continuous, the duty can be shared between several pumps.

Where the flow rate is relatively small a two pump set can have each pump sized to cater for 100% of the duty, one pump acting as duty and one pump acting as standby.

As an alterative arrangement each pump can be sized to 60% of maximum demand. One pump acting as duty which will operate most of the time. The second pump will operate to assist the duty pump in peak demand periods, giving more than adequate support.

On systems with higher fl ow rates it may be more economical to split the duty between three pumps. Each pump can be sized to 50% of maximum demand.

Special Requirements

All booster sets can be easily adapted to meet most customer specific requirements. If you have a spe- cial requirement please contact our head office who will be pleased to offer technical advice and design a system tailored to your specific requirement.

CEA, CEAM, CA, CAM

Close-coupled, threaded centrifugal electric pumps, single impeller (CEA) and twin-im- peller type (CA). Stainless steel pump body, seal housing, impeller and diffuser. Continuous duty, enclosed IE2 motor with external ventilation and finned casing made of aluminium alloy.

HM

Multi-stage centrifugal horizontal electric pumps with power up to 0.9 kW. Stainless steel pump body, seal housing and diffuser. Impellers made of technopolymer. Continuous duty, enclosed IE2 motor with external ventilation and finned casing made of aluminium alloy.

e-SV

Multi-stage centrifugal vertical electric pumps with high power efficiency up to 22 kW. Stainless steel pump body, seal housing, diffuser and impellers. Continuous duty, enclosed standard IE2 motor with external ventilation and finned casing made of aluminium alloy.

Selecting a Booster Set

The first thing to do when selecting a set is to determine the volume of water required and the pressure it must produce.

Calculating the Flow Rate

The volume of water called water requirement depends on the type of users, e.g. homes, offices, schools, as well as their number. The theoretical requirement is the total volume of water required by all the users. In actual fact, since it is very unlikely that there should be a simultaneous demand by all the users, the real requirement is lower than the theoretic one.

Calculating the Head

The pressure required depends on the type of user. A number of factors must be taken into account, including the height of the building, the suction conditions and the fl ow resistance in the pipes.

Selecting a Booster Set

According to the required fl ow rate and head values, it is possible to identify the most suitable type of electric pump. Single pump booster sets are normally only selected on systems that do not have a critical demand, I.E where an alternative supply is available. On two-pump sets the pumps normally act as back-up for one another. A singlepump is normally sufficient to provide for average requirements, while in conditions of high demand the back up pump may be called in to assist. With the cyclic changeover function duty assignment is rotated to ensure both pumps remain active and with even running hours, so wear is uniform and the use factor is reduced for longer pump life. This system also ensures continuity of operation in case one of the pumps needs maintenance.

Vessels

Lowara have included an 8lt vessels with all Teknospeed sets and a 24lt vessel for each pump on all other sets normally fitted on the discharge pipe in front of each pump giving a more compact design.

Assesment of Probable Demand

The method adopted is based on loading unit values as detailed in the Plumbing Engineer- ing Design Guide published by the Institute of Plumbing.

When designing a hot or cold water supply system an assessment must be made to obtain the maximum probable simultaneous demand.

Depending on the type of services being provided it rarely occurs for all the appliances to be used at the same time therefore the design usually allows for a peak usage which is less than the maximum.

Probable demand will depend on, the type of building and its use, type of appliances in- stalled and frequency of use.

The simultaneous demand in most installations can be calculated with an adequate degree of accuracy using the loading unit concept.

The usage patterns and types of appliances in different installations will vary greatly.Sports and Leisure centres for example are usually calculated directly by the fl ow rates of each appliance, without diversity factors. Each case will need to be looked at in its own right and assessed accordingly. Judgement of the designer must prevail.

Loading unit values vary for each type of appliance. A loading unit has no precise value in terms of litres per second.See loading unit table below.By multiplying the total number of each appliance bythe appropriate loading unit number and adding theresultant totals together, the recommended fl owcan be read from chart.

| Appliance |

Loading Unit |

Recommended Flow L/s |

| WC |

1,5 |

0,12 |

| Wash basin (hot & cold) |

3 |

0,3 |

| Sink (hot & cold) |

6 |

0,4 |

| Bath (hot & cold) |

20 |

0,6 |

| Shower (hot & cold) |

10 |

0,24 |

| Washing machine |

2 |

0,3 |

Working Example

A block of standard flats containing a total of 70 dwellings

Each standard flat is assumed to have:

- 1 x Hand basin hot & cold = 3 L/U x 70 = 210

- 1 x WC cold only = 1.5 L/U x 70 = 105

- 1 x Shower hot & cold = 10 L/U x 70 = 700

- 1 x Sink hot & cold = 6 L/U x 70 = 420

The head required in a boosted cold water system consists of three components, static head, residual pressure and system friction losses. The values of these three components are added together to give the total required head at the system flow rate.

Static head (He): This is the difference between the break tank low water line and the highest discharge point in the building. If the height of the build is not known, then 2.8- 3.0 metres per floor can be used to assess the building height.

Residual pressure (Hr): This is the pressure required at the highest outlet device, normally 20 metres. Note: Some modern showers may require higher pressures.

System friction losses (Hc): The total losses through pipework, pipework fittings, valves, PRV's and all other equipment fed through the pumpset must be added to find the total system losses. On conventional systems that do not include excessive runs of pipe or specialised components a rough guide would be to allow 0.05 metres friction loss for each metre of static head.

Example:

| Static head (He): Building height four floors @ 2.8m each |

= 11.2m + |

| Residual pressure (Hr): Pressure at highest outlet |

= 20m + |

| Friction loses (Hc): 11.2 (static head) x 0.05 |

= 0.56m |

| Total pump head required (H) |

= 31.76m (3.11 Bar) |

Pressure Limitations

The designer must ensure that adequate precautions are taken to ensure that the system is capable of withstanding the closed valve head produced by the pump set. In cases where closed valve pressures cannot be tolerated, pressure reducing valves should be fitted down stream of the booster set.

Velocity

Pipework within the system should be sized to limit the velocity to the figures stated in table below. Higher velocities will lead to excessive noise, ware and higher

running costs

| Pipe Size |

Suction Pipe m/s |

Delivery Pipe m/s |

| Less than 80mm |

0,46 |

0,91 to 1,07 |

| 100-150mm |

0,55 |

1,22 to 1,52 |

| 200mm |

0,76 |

1,68 |

| 250 and above |

0,91 |

1,82 to 2,13 |

Booster Sizing

What information do we require to size a booster set?

As a minimum we need to know:

- The total flow rate, or information to assess this.

- The total head at flow rate, or the height of building.

- If the pumps are to operate under positive head, or suction lift conditions.

- Where the set is to be sited, I.E. basement or roof.

- Preferred choice fixed or variable speed

Additional information if available:

- How to split the duty for particular applications I.E. duty