- Home

- Case Studies

- Shepherd Neame

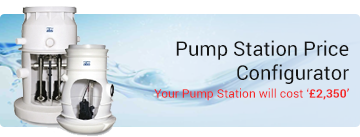

The 3 pump stations were required for the Kegging area, Bottling Hall and Main Brewery, each incorporating DN100 EMU duty / standby pumps suitable for handling foul / surface water containing concentrations of caustic and phosphoric acid when 'Cleaning In Process'.

| Manufacture |

Southern Pump Services Engineering |

| Product |

Wilo 6 x FA100 4kW - CERAM coated |

| Chamber |

3 x Below Ground GRP Tanks |

| Contract |

Shepherd Neame - Cleaning In Process |

| Value |

60k |

The EMU pumps each sized at 20 l/s, were CERAM coated along with the base elbows and guide rail claws. The GRP pumping chambers had a special gel-coat applied to cope with the pumped medium. DN100 ABS internal pipework, suitable elastamors / materials for valves, stainless steel flange backing rings / boltsets / lifting chains / guide rails (polished) and specially manufactured inlet connections to suit lined clay drainage pipework laid in each of the working areas.

The Control panel cabinets were manufactured in 316 stainless steel and required certain control regime via level float controls with various output signals interfacing with the Brewery’s BMS system.

All the equipment was supplied and commissioning to the Brewery’s satisfaction within 8-10 working weeks, completion June 2011.