- Home

- Ancillery Equipment

- Chemical Dosing

Pump stations in the immediate vicinity of food producing premises often suffer from thebuild up of fat within the wet well chamber.

Fat brought down the pump station inlet pipework floats on the water level within the wetwell and slowly accumulates on the equipment mounted within the wet well and on thechamber walls themselves.

Most proprietary solutions to this problem rely upon a method of keeping the fat insuspension rather than letting it coagulate.

Southern Pump Services Limited can now provide a new solution based upon a newconcept in fat control for new or retro fitting to existing wet well chambers.Southern Pump Services Limited can now provide and deliver effectively, a mix of fourspecially selected micro-organisms to digest naturally the grease, proteins, starch andcellulose of enzyme dosing.

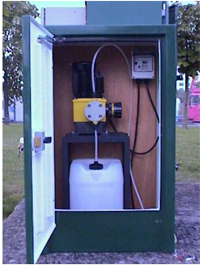

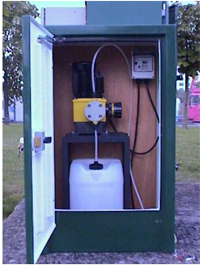

A simple and compact dosing system provides a high-pressure supply of chemical to aspray bar mounted within the wet well, enabling you to regulate either the flowrate or runtime which can almost infinitely control the quantity of chemical delivered.The spray bar is equipped with misting nozzles to allow the dispersal of a very fine dropletbased mist into the wet well. This mist descends onto the entire surface of the wet wellallowing the digesting agent to make contact with all deposits whether on the watersurface or on the chamber walls.

- EDC “Enzyme Dosing Chemical” (for up to 6 months use*)

- LMI dosing pump (1~ 230V, 50Hz)

- Fabricated pump stand to suit site conditions

- Spray bars

- Suction and Delivery Pipework

- Injection fittings

- Control system

- Health and Safety Paperwork

- Standard General Arrangement Drawings

- (Optional) GRP kiosk 1250mm(High) x 750mm(Wide) x 400mm(Deep)

- All kiosks come with a varnished backboard & locking facility

- Other materials of construction available , Plypropylene , Steal and Stainless Steal are just few

PUMP AND PUMPING EQUIPMENT MUST BE MOUNTED WITHIN 4 METRES OF WET WELL CHAMBER

* Extra EDC “Enzyme Dosing Chemical” available at an additional cost

Southern Pump Services Limited recommends a minimum six months routinemaintenance contract be taken out with this equipment which should alsoinclude of replacement EDC “Enzyme Dosing Chemical”

Southern Pump Services Limited would be pleased in offering assistance to assemble andposition all equipment within the confines of wet well chamber, connect the various spraybars, injectors, suction and delivery pipework test and commission all equipment on sitecontact Southern Pump Services Limited for further details

THIS WORK WOULD BE CARRIED OUT BY A TEAM OF CONFINED SPACE ENTRYTRAINED ENGINEERS WITH ALL THE NECESSARY HEALTH AND SAFETYEQUIPMENT AND CERTIFICATION